One area that has dominated headlines these past months during the global pandemic is supply chain and manufacturing. A shortage of goods, equipment and people has meant that global supply chains and manufacturing practices have come under extreme pressure and in some cases failed. What this has highlighted is the overriding need to collect, analyse and act on data that is available but widely untouched or accessed today in the manufacturing industry.

Challenges in a data driven manufacturing environment

Integration between different vendors and disparate technologies which is minimal (or in some cases non-existent), presents a massive challenge when trying to collect data. In most cases this leads to silos of data that are frankly useless as no context of the end to end process or supply chain can be understood.

Collection of data. Unlike an IT infrastructure, Operational Technologies infrastructure is not necessarily instrumented with agents or managed and monitored to the same extent. This presents a visibility and observability gap when it comes to status and availability of critical systems. It can also have a direct effect on availability and performance.

Compliance and security are a challenge due to the diversity highlighted above. With more and more processes and data in the cloud, security is paramount. From a compliance standpoint this is where understanding your supply chain is key; especially from a customer perspective. More on this later.

Is an Intelligent Data Platform the solution?

There is lots of analysis about the challenges of collecting data from different vendors and disparate technologies. To meet this challenge, we have seen the rise of platforms – lots of them! But the real key here is that organisations are starting to realise that having many platforms exacerbates the problem.

The answer?

A single platform capable of ingesting data from any source to create business and operational value!

The data should be able to be collected from across the business regardless of type, format, or source.

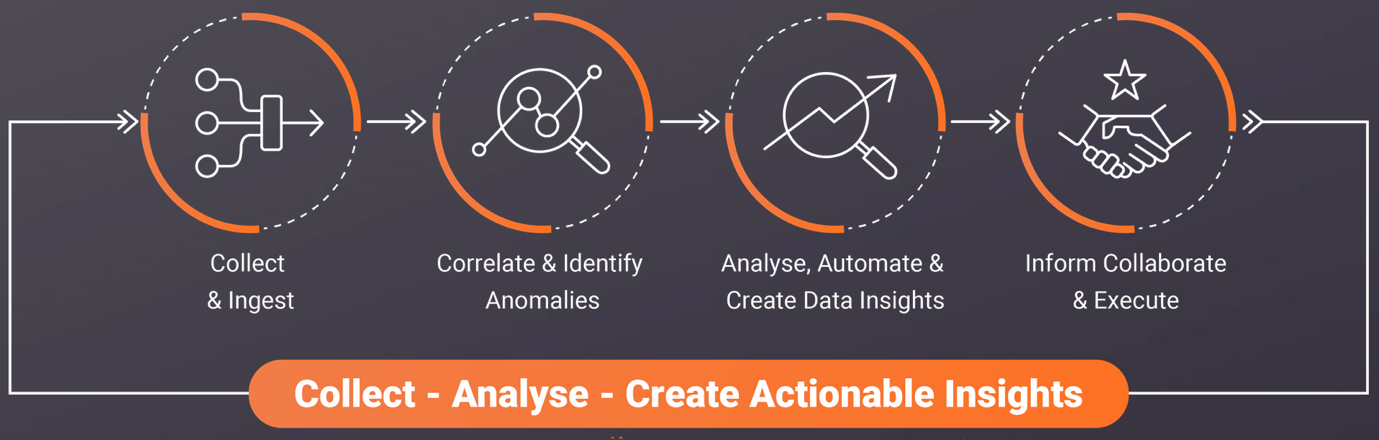

The graphic below depicts the stages through which the data should travel.

Collect – & Ingest– the platform should have collection capabilities spanning not only the IT infrastructure (from mainframe to multi-hybrid cloud infrastructures) but also from Operational Technologies (sensors, industrial internet of things, machinery, and plant). In fact, it should collect from any source that can create an event, alarm, SNMP trap or log file.

Analyse – the platform should be able to perform rapid analysis of information using machine learning algorithms and modelling specifically tailored for different industries. With only 0.05% of data being used by businesses, finding that needle in the haystack is key!

Create/Gain actionable insights – the platform should drive better business outcomes by making an organisations data work for the organisation. From IT, OT to line of business to enhancing customer experience, we are seeing data being used for process improvement, competitive advantage, environmental requirements, predictive maintenance and supply chain management and compliance.

Speaking of supply chain compliance, we are witnessing significant impact on some organisations in this industry in terms of hefty fines being handed out to those who have neglected this area of their business. Along with the shortage of goods, materials and people, there is a need to augment or supplement with the use of data, ensuring business supply chains become and remain robust, available and performant. Check out our most recent blog on the topic highlighting how you can bring trust and compliance to your supply chain through an Intelligent Platform.

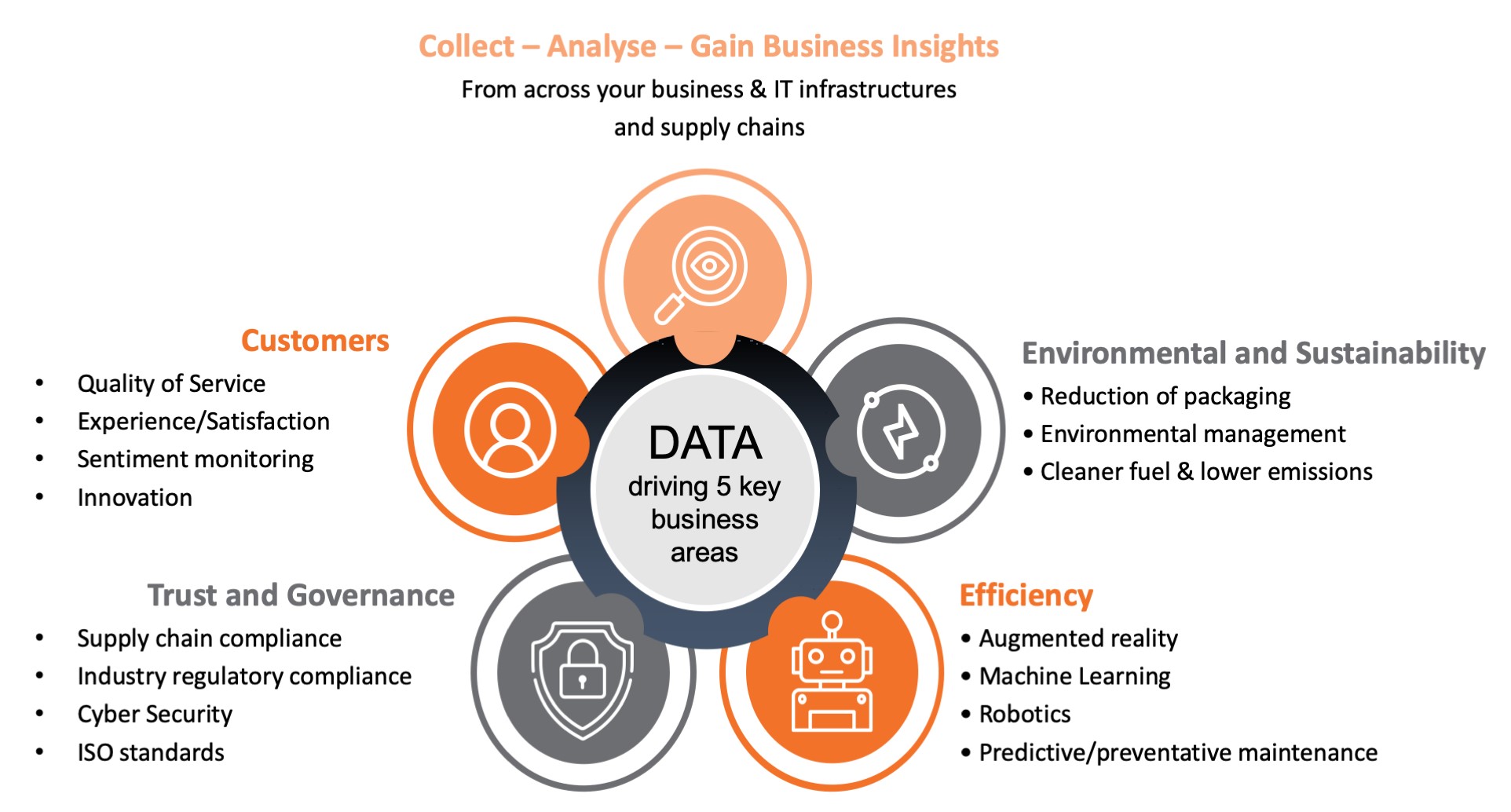

Data driving 5 key business areas in manufacturing

The graphic below shows 5 areas data from inside and outside an organisation that can be used to support different parts of the business. The list is not confined to those in the graphic, but in my opinion these are the ones where significant value can be gained immediately.

Today and going forward data will be the cornerstone strategy for any manufacturer who is considering a new plant or redeveloping an existing one. A robust data architecture will be the major consideration of how the manufacturing process will operate to maximise this.

This where the iMonitor ‘Intelligent Data Platform’ can accelerate your data journey by collecting and analysing your data to create optimum efficiency as well as driving predictive maintenance, trust and compliance within your supply chain and providing feedback loops and ModelOps to AI, AR and Machine Learning capabilities.

For more information on the iMonitor data platform

why not sign up for our blogs or

visit our website at www.imonitor.ai

ABOUT THE AUTHOR

David Metcalfe is Principal Consultant at iMonitor.

David is an experienced IT Consultant with a flair for the architecting and provision of IT solutions across a variety of industries.

David has been involved in many successful pre and post sales opportunities, delivering across multiple industries, with a major focus on the service management and ongoing support of these implementations/projects.